REUSE, REPAIR, RECYCLE

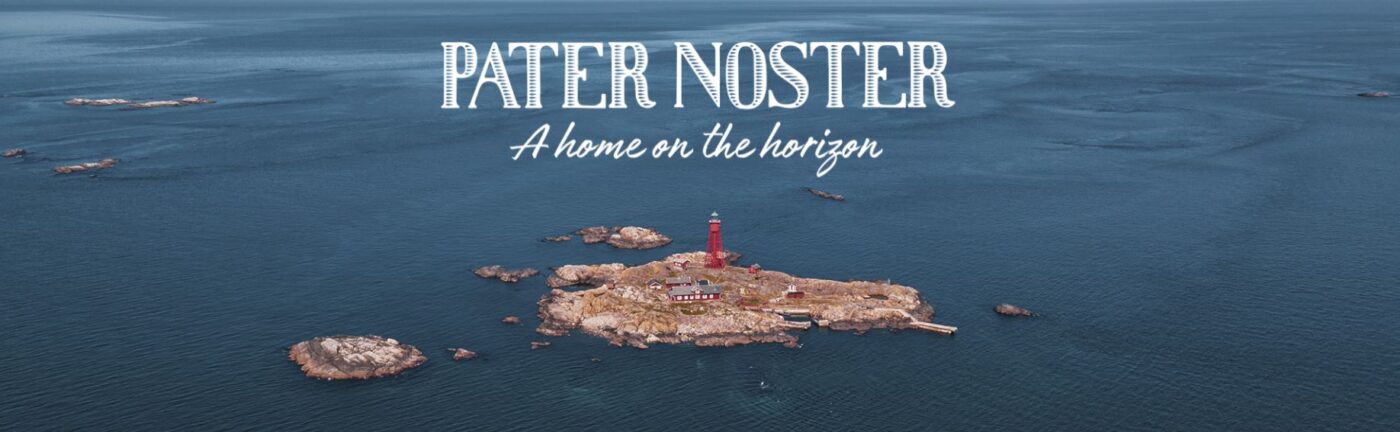

The employees at Pater Noster are dressed in Swedish made, sustainable apparel made from ocean plastic and timber waste.

As big fans of the Home on the Horizon, we at Reparell are delighted to share our ideas of #SlowFashion with all friends of the King of Lighthouses.

As Pater Noster is a magical destination, this garment has its own magical quality and origin. We are proud to present our #CottonFree line, crafted in Sweden using recycled and/or compostable materials such as #WoodPulp and #OceanWaste.

In full transparency, please scroll down to find information about the materials and production units/methods we use.

As for Circularity, all Items are provided with a QR code. The code takes the user to a web page with information about the materials and what to do when the item is worn out so we can recycle it together with similar materials in a hopefully very distant future.

“The greatest mistake is to do nothing because you can only do a little” –Zig Ziglar

“Making the world a better place, one button at the time” – Emil Pettersen , founder Reparell AB

THE MATERIALS WE USE; PLEASE CLICK ON LOGOS FOR WEBSITES

SEAQUAL® YARN is spun by ANGLES TEXTIL SA

Marine litter from beaches, oceans, rivers and estuaries, is collected by clean-up programs. It is then sorted, cleaned and transformed into Upcycled Marine Plastic by SEAQUAL INITIATIVE approved partners.

SEAQUAL INITIATIVE

Together for a clean Ocean

TENCEL™ cellulosic fibers (#WoodPulp) help maintain environmental balance by being integrated into nature´s cycle

The production units: Guimarães - Borås - Kinna

Family owned since 1939, LEMAR, a Portuguese semi-vertical weaving company are the producers of sustainable fabrics for activewear, sportswear, beach and casualwear. Focus is on high performance technical fabrics

For the Pater Noster collection, sustainable fabric wasn’t enough. To be really sustainable all items are produced in Sweden. Producing locally in Borås with the help of TextilFABRIKEN we have been able to produce in lower quantities, reducing the risk for overproduction. Local production also has advantages that include reduced emissions and transportation costs.

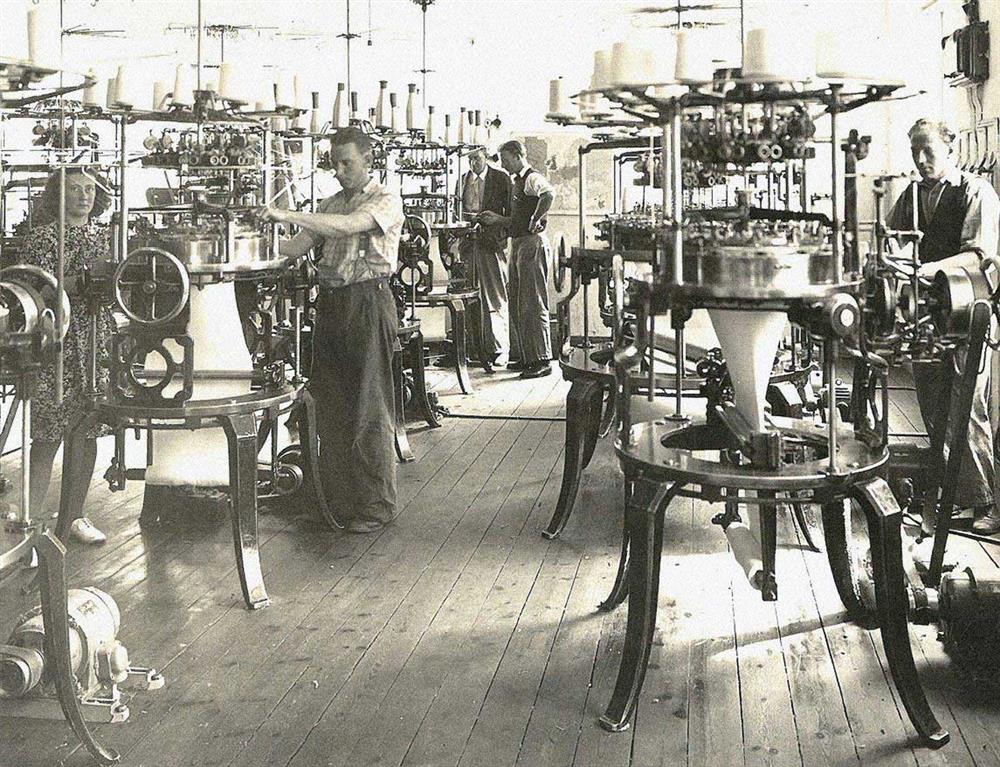

In Kinna approx. 60 km west of Gothenburg, knitting factories have their roots in the Swedish innovative textile industry.

With experience dating back to the 1920s, we are taking advantage of the level of education, sense of quality and ingenuity, on site, in Sweden. With the results in hand, we can proudly state that we have made the right choice.