What We Make

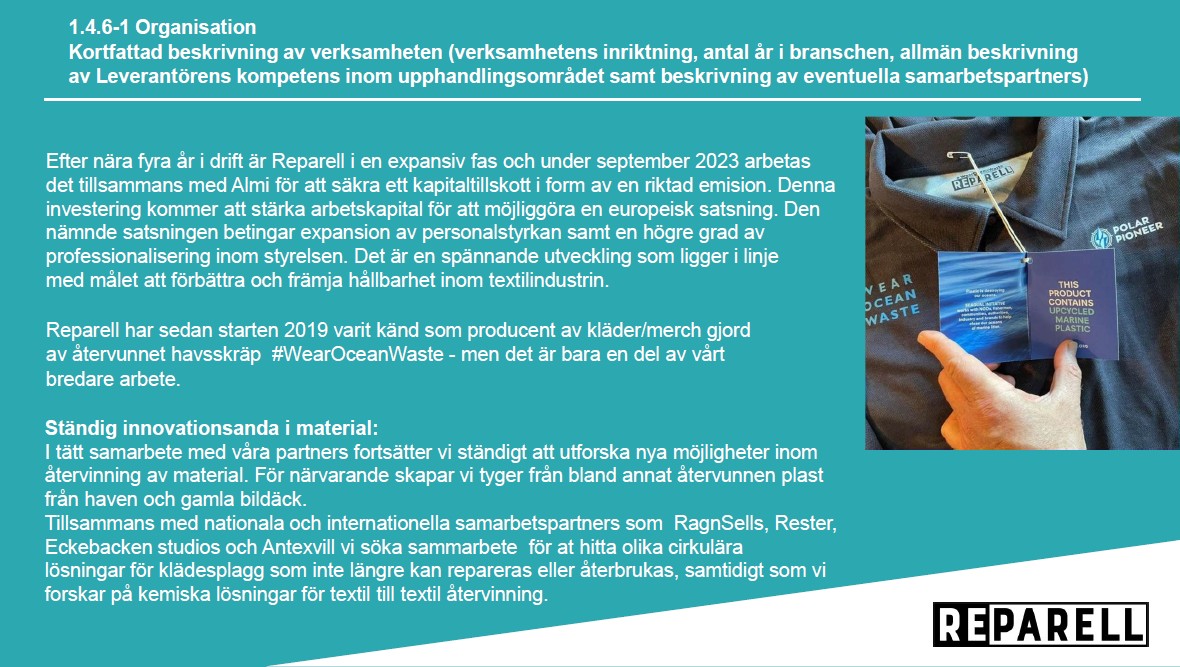

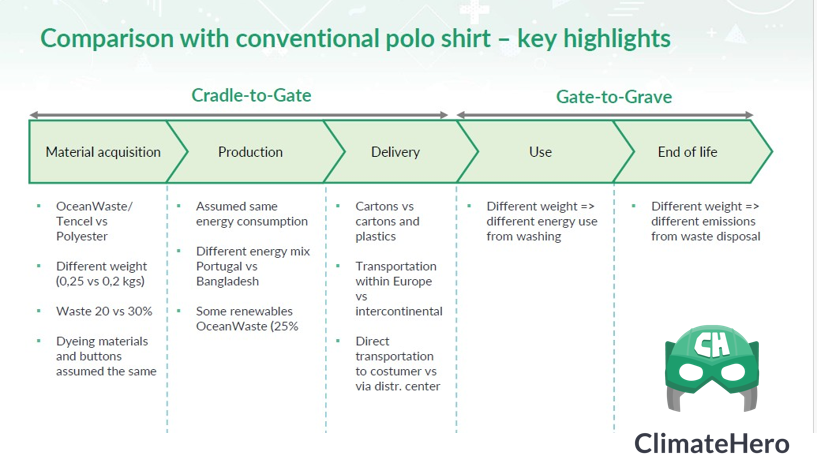

From Yarn to Garment: Every product we make starts from one of our three European yarns — OceanWaste, AutoWaste or Tencel.

Produced on demand in Portugal, within 70 km from yarn to finished garment.

No warehouse. No overproduction. Just verified quality and measurable impact.

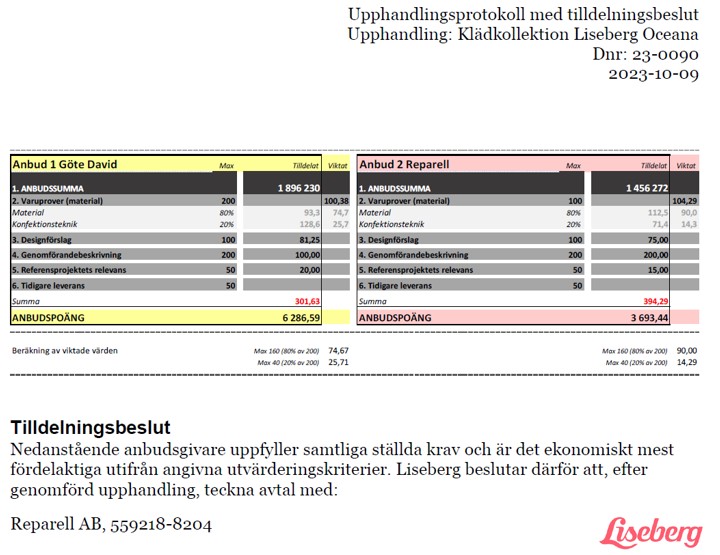

Liseberg Oceana by Reparell

A concept collection created by Reparell AB for the Oceana water world at Liseberg in Gothenburg.

Reparell won the four-year framework agreement after achieving the highest total evaluation score, with sustainability and local production rated almost twice as high as the nearest competitor.

Each garment was developed using OceanWaste and AutoWaste yarns — recycled PET from ocean waste and recycled polyamide from end-of-life tyres — and produced on demand in Portugal within 70 km from yarn to garment.

The project demonstrates Reparell’s capability to deliver circular, traceable and design-driven uniform solutions for large-scale hospitality and entertainment environments.